Need help? Call us on 0800 772 3688 or 0208 905 1555

Prefer email? Contact us via sales@futureshop.co.uk

Need help? Call us on 0800 772 3688 or 0208 905 1555

Prefer email? Contact us via sales@futureshop.co.uk

Atlas Atlas Asimi LUXE 2 XLR to 2 XLR Audio Cable is available in four standard Nappa leather finishes;

Custom bespoke finishes are available on request. Please contact us on 0800 772 3688 for more details.

The Asimi XLR is a state-of-the-art interconnect designed to be effectively ‘invisible’ in the replay chain and to reveal the entire content and ambience of the recording without any sense of exaggerated detail or brightness. The Asimi XLR is engineered to maximise the performance of ‘high-end’ audio systems by achieving maximum signal transfer.

The original aim of the Atlas Asimi project was to take a completely fresh look at cable design and, where necessary, to develop new techniques to create a cable which would satisfy the most critical listeners for years to come. For this latest generation version, Atlas again went back to basics, re-assessing their existing design & manufacturing processes, exploring different construction methods and experimenting with new materials.

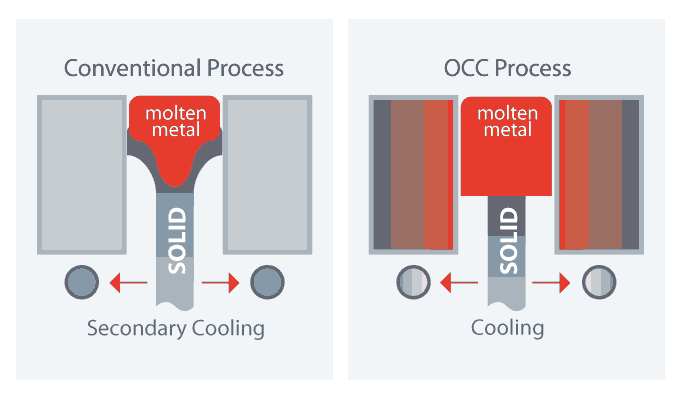

The Asimi XLR features pure silver conductors, manufactured using the highest-quality ‘Ohno Continuous Cast’ technique for drawing pure silver. Silver cables have a reputation for poor sound quality in some quarters, Atlas believe the Asimi definitively shows the problem is with low grade materials and poor manufacture, resulting in a cable with a coarse grainy structure which compromises sound quality. By contrast, in the manufacture of Asimi, Atlas maximise the silver’s conductivity by ensuring that there is typically one grain in approximately 125 metres of conductor, allowing the signal a continuous unbroken path –in effect, the signal has a faster, cleaner and more direct path to follow.

Theoretically, the best dielectric (insulation layer) is air, but realistically a dielectricis needed to protect the conductor – although all conventional dielectric materials impose their own signature distortion and loss on the signal. Atlas developed a new technique, using a microporous PTFE (Teflon™) tape, which is wound around the core conductors, then covered again and stabilised using a protective FPE (Flexible PolyEthylene) dielectric. Atlas' process allows the required conductor geometry to be maintained and offers greater manufacturing consistency.

tlas use cold-weld terminations wherever possible, including their current generation ‘dark Chrome’ XLR connectors. By reducing the number of materials and break points in the signal path, Atlas' objective is to minimise discontinuity and loss in the signal path, resulting in more consistent construction and improved audio performance.

The Atlas XLR combines a lightweight aluminium alloy body with precision-fit OFC/OCC connectors and solder-free construction.

The Ohno continuous casting method re-heats the extrusion as the molten copper is forced out of the mould and very slowly and gradually draws the grain or crystal down the conductor''s length, creating a ‘single crystal structure.’ The benefits are obvious, with almost no crystal boundaries, the audio signal is no longer impeded down the copper wire and more information and detail is delivered faithfully to the receiving equipment.

Silver, with its lower resistivity, is a better conductor than copper, but any conductor, whether silver or copper, must have a reasonable cross-sectional area when used for audio applications. Silver is much more expensive than copper and, in order to keep costs within reason, the cross sectional area of silver audio cables are often compromised and the resulting sound is ‘bass light.’ Good silver cables are, however, fast, dynamic and seamless through the audio spectrum and provide exceptional detail and instrument resolution. The Atlas Asimi cables employ OCC silver conductors and in the case of the Asimi speaker cable, these are a substantial 3.5 sq mm in overall size in order to provide wide bandwidth and superior definition.

PVC (Poly Vinyl Chloride) is cheap to produce and, as such, is the most commonly used insulation in AV cables. However, PVC is the worst quality insulation a Hi-Fi or AV signal can encounter as its high loss causes a significant reduction in signal velocity. PVC is better suited to power cables and should be avoided in Hi-Fi and AV signal cables.

Other dielectrics in common use are Polyethylene, Polypropylene and Polytetrafluoride Epoxy (better known as PTFE (Teflon™) or Teflon,) and the new and unique Atlas (PTFE).

Microporous PTFE (Teflon™) is a unique, low density dielectric material, phase stable at room temperature, which offers significant performance improvements over solid PTFE (Teflon™) dielectric designs.

The table below shows the properties of a selection of dielectrics. Though not used as a dielectric in Atlas' cables, PVC is included for comparison purposes.

| Dielectric Material Comparison (0.3mm Diameter) | |||||

| Property | Polyvinyl Chloride (PVC) |

Foamed Polyethylene (PEF) |

Polypropylene (P.P) |

Teflon (FEP or PTFE) |

PTFE |

| Dielectric Constant (@ 50 -106Hz) |

4-8 | 2.3 | 2.25 | 2.1 | 1.3 |

| Dielectric Strength (kV mm-1) |

23-30 | 30-50 | 30-50 | 20-25 | N/A |

| Loss Tangent (% @ 50 - 106Hz) |

8-15 | 0.02-0.05 | 0.02-0.06 (@ 106Hz) |

0.02-0.07 | N/A |

| Volume Resistivity (Ohms.cm @ 20°C) |

1012-15 | >1017 | 6.5x1014 | >1016 | N/A |

| Tensile Strength (Kg mm-2) |

1.0-2.5 | 1.0-2.0 | 3.0-4.0 | 1.9-2.2 | 1.0 |

| Melting Point (°C) |

-130 | 112-120 | 155-160 | 275 | 275 |

| Max. Continuous Operating Temp. (°C) |

60 | 75 | 90 | 200 | 260 |

| Min. Operating Temp. (°C) |

-15 to -40 | <-60 | -5 to -45 | <-60 | -250 |

A pair of identically matched conductors (one for signal path, the other acts as the return conductor) enclosed within a non-conducting screen. Combined with Atlas' dd (dual drain) system which avoids distortion of the screening braid during assembly – this can change the impedance and therefore the performance of the cable.

Normally screened cables suffer from screen distortion when they are prepared for production. (If you've ever wired a plug or connector which uses a screened cable, you've done this yourself, cutting back and probably twisting the screening braid for termination). This distortion of the screen has a measurable impact, effectively changing the impedance and therefore the performance of the cable.

Atlas' ‘dd’ configuration is based on a simplified version of the techniques they developed for their top-of-the-range Mavros and Asimi interconnects. Twin symmetrical drain wires (each attached to 180° segments of the plug) are inserted between a 100% copper/Mylar™ foil and screen. The unique dd system connects the screen effectively to the cable return/plug interface, meaning the cable can be terminated without distorting, twisting or mechanically stressing the precision-laid screen. The benefits are in maintaining a consistent low impedance load to the plug, and a total 360° screening against noise and signal loss caused by RFI (Radio Frequency Interference).

|

|

|

“The bespoke leather sheath is also something not seen elsewhere and adds to the luxury feel. Plug these into your system and you will definitely hear a difference.” (Read More) Cable Review - Hi-Fi World - April 2019

|

Atlas Cables are a major producer of interconnects and cables in the United Kingdom of Great Britain. All products are researched, developed and most are assembled in the Atlas purpose built factory in Scotland.

Many of these products are unique and use advanced techniques of production or manufacture in order to bring to the user the very finest quality products. With each new model we continue to push the boundaries of reliability and performance. It's little wonder then, that Atlas Cables have had so many mile-stone advances in the past and that Atlas Cables have secured so many awards in comparative tests against other products.

Orders received before 4.30pm Monday to Friday (excluding Bank Holidays) are usually dispatched the same day by FIRST CLASS post (unless premium postal or timed courier services are selected), subject to stock availability. Over 98% of our orders are usually delivered the next working day including Saturdays.

Standard delivery is usually within 2-3 working days, although 98% of all orders are delivered the next working day including Saturdays . In extreme cases, such as delivery to the Highlands and Islands, this may take 3 days.

All items are fully insured and come with an invoice from Futureshop.co.uk. We use the Royal Mail for delivery of small packages and DPD or Interlink Express for items that weigh over 2KG. Items over 2KG are fully insured and will usually be delivered within 48 hours of placing your order Monday to Friday subject to stock availability. For International orders, we use FedEx Services where customers have selected this option.

Please note, special orders for non-standard cable lengths or custom-made cables may be subject to longer delivery time-scales. This may vary from manufacturer to manufacturer.

We offer 'Free UK delivery on orders over £99' subject to the following terms & conditions:

Free Delivery on orders over £99 utilises Royal Mail First Class postal service for items weighing under 2KG. For items weighing over 2KG, we use DPD or Interlink Express next working day services which deliver from 9.00am to 6pm within mainland UK.

Free Delivery for orders over £99 excludes Royal Mail Special Delivery Services and timed next day delivery services by DPD or Interlink Express.

We have 99.9% of the UK covered With Royal Mail Next Day Special Delivery. We guarantee delivery to most UK addresses by 1pm the next working day. This includes Northern Ireland, Jersey and Guernsey. Some places take longer to deliver to but we still guarantee delivery within three working days by 5.30 PM.

For the Next Day Special Delivery service, orders must be received by futureshop.co.uk by 4.30pm weekdays. Orders after the 4.30pm deadline cannot be guaranteed for same day dispatch.

Please note, Royal Mail Special Delivery for next working day may not be possible where non-standard cable lengths are ordered. If this is the case, the item will be shipped via The Royal Mail Special Delivery service as soon as the cable is custom made.

For orders weighing over 2KG, we reserve the right to ship items using Next Day Pre-Noon Courier Services where Royal Mail Special Delivery option has been selected.

We accept orders from all Channel Islands including Alderney, Jersey, Guernsey and Sark. Unless you select a premium service, Items weighing under 2KG are delivered using our standard UK delivery option above. For items weighing over 2KG, a surcharge may be applied for all deliveries to the Channel Islands as well as Northern Ireland.

Deliveries to EU member states are subject to 20% VAT. We offer the following shipping services:

Deliveries outside of the EU are not subject to 20% VAT and so the 20% tax on items is automatically deducted when you login or register.

We offer the following shipping services:

Where the actual weight of the package significantly exceeds the shipping cost charged on orders, we may write to you for an additional shipping charge. For larger orders, items may be shipped in multiple packets.